Environmental Policy

EIKEI Group is dedicated to addressing climate and environmental concerns. It has established an environmental management system compliant with ISO14001 to demonstrate its commitment to ecological sustainability and has obtained certification. By implementing systematic management, we have developed environmental policies as the cornerstone for addressing environmental issues within the company. We strictly adhere to domestic ecological, safety, and health regulations and regularly conduct educational training to enhance environmental safety awareness, thereby ensuring a safe and healthy working environment for employees.

Energy Statistics

Energy Statistics

In line with national energy regulations and international trends in energy conservation and carbon reduction, EIKEI promotes energy management projects through efficiency improvements and energy transformation, including energy-saving programs and renewable energy promotion programs. Following the Ministry of Economic Affairs' "Regulations on Energy Users Setting Energy Conservation Targets and Implementation Plans," we continuously aim for an annual electricity saving rate of 1%. Since EIKEI operational activities are mainly office-based and do not involve product production or manufacturing, energy use primarily consists of fuel for official vehicles and office electricity consumption. Therefore, EIKEI Group energy-saving strategy focuses mainly on office energy control. On the other hand, to actively promote energy transformation, EIKEI has conducted evaluations for the installation of renewable energy and the procurement of green electricity. Green electricity was procured in 2023 and will be used starting in 2024.

Total Energy Consumption at Each Location (GJ)

| Taiwan Office | Thailand Office | Hong Kong Office | Energy Intensity (GJ per million NTD) | |

|---|---|---|---|---|

| 2022 | 268.32 | 1147.25 | 6.06 | 0.86 |

| 2023 | 285.91 | 1098.62 | 5.14 | 0.83 |

1.Gasoline calorific value = 7,800 kcal/L, electricity calorific value = 860 kcal/kWh, coefficients are sourced from the Energy Product Unit Calorific Value Table by the Bureau of Energy, Ministry of Economic Affairs.

2. Unit of energy consumption: Gigajoules (GJ)

3. Energy types are non-renewable energy, including gasoline usage and purchased electricity.

4. Energy intensity = Absolute energy consumption (gasoline + purchased electricity) / Annual revenue (million NTD)

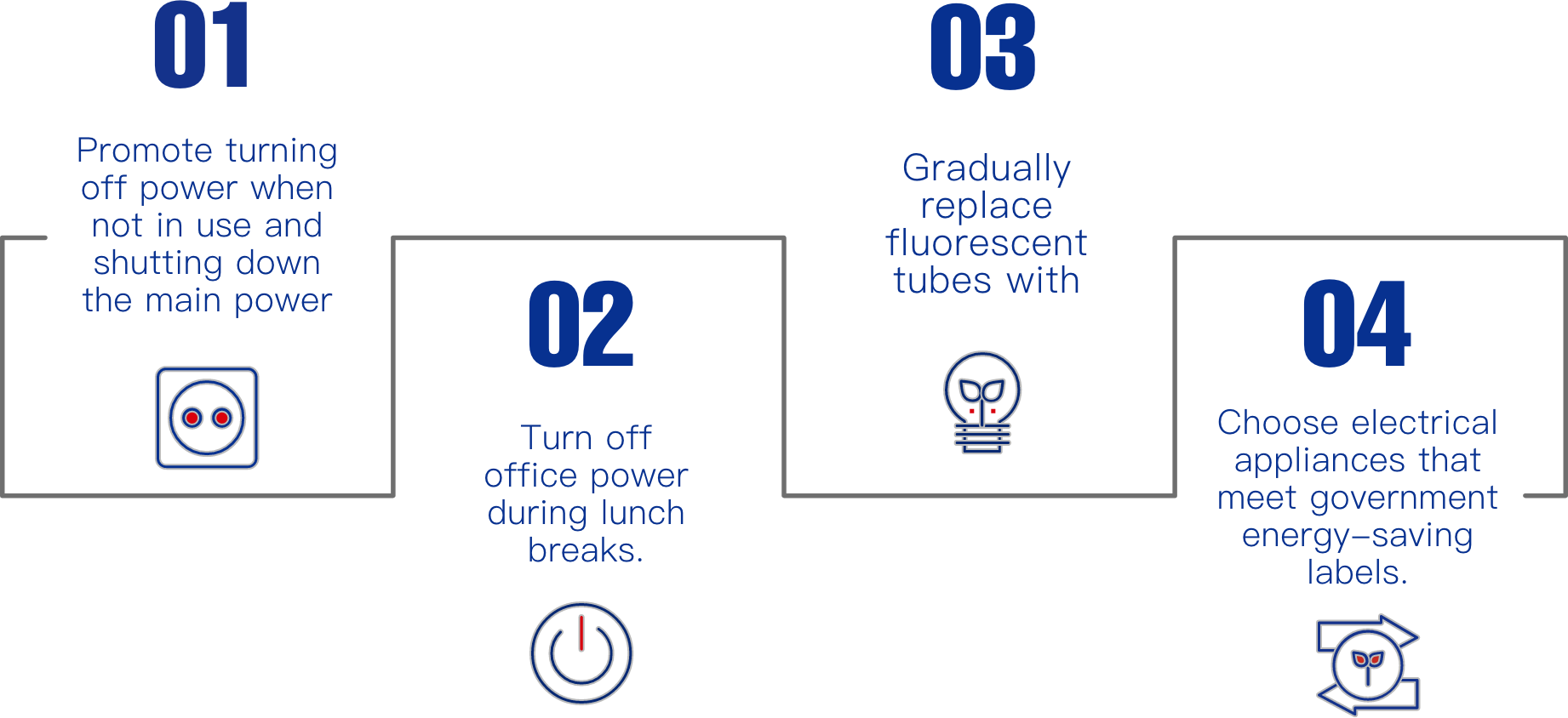

Energy Conservation Policy

Greenhouse Gas Emissions

In response to the increasing societal focus on greenhouse gas emissions and climate change issues in recent years, EIKEI actively supports the global trend of carbon reduction. Greenhouse gas inventory has been incorporated as a key initiative in our operational management, and we are simultaneously planning the best feasible carbon reduction solutions to actively reduce greenhouse gas emissions. In 2023, EIKEI Group greenhouse gas emission intensity was 0.09 tons CO2e per million NTD. The main emission sources were fuel for official vehicles, accounting for 25.70% of the total, and electricity for office and warehouse operations, accounting for 74.30% of the total.

Greenhouse Gas Emissions at Each Location

| Taiwan Office | Thailand Office | Hong Kong Office | Total Emission Intensity | |

|---|---|---|---|---|

| 2022 | 0.066 | 0.179 | 0.001 | 0.1 |

| 2023 | 0.062 | 0.155 | 0.001 | 0.09 |

Please take note of the following information:

1.Unit of greenhouse gas emissions: Metric tons of carbon dioxide equivalent (tons CO2e).

2. Emission factors: These are calculated using the Greenhouse Gas Emission Factor Management Table 6.0.4. The 2022 electricity emission factor is 0.495 kg CO2e/kWh, announced by the Bureau of Energy, Ministry of Economic Affairs in 2023. The 2023 electricity emission factor is 0.494 kg CO2e/kWh, announced by the Bureau of Energy, Ministry of Economic Affairs in 2024.

3. Global Warming Potential (GWP): The values are primarily based on the information published in the IPCC 2021 Sixth Assessment Report (AR6).

4. The inventory boundary includes the Taiwan branch, Hong Kong subsidiary, and Thailand subsidiary. Emission sources include mobile combustion sources, refrigerant leakage, and purchased electricity.

5. Greenhouse gases included are carbon dioxide (CO2), methane (CH4), nitrous oxide (N2O), and hydrofluorocarbons (HFCs).

6. Greenhouse gas emission intensity is calculated as (Scope 1 + Scope 2) divided by Annual revenue (million NTD).

Water Resource Management

Due to the risks of water scarcity posed by climate change and extreme weather, reducing dependence on water resources and improving the company's water recycling rate is crucial. EIKEI Group has adopted the World Resources Institute (WRI) Aqueduct Water Risk Atlas for comprehensive water risk identification. The results show that none of the operational locations are in high water risk areas.

Conservation Policies

EIKEI Group's operations are mainly office-based and do not involve product manufacturing, so water usage is primarily for office activities. EIKEI Group continues implementing measures to improve water resource management, including providing educational training and promoting water-saving slogans in pantries and restrooms to increase employees' awareness of water conservation.

In 2023, the Taiwan branch replaced office toilets with water-saving devices, expected to save 73,000 liters of water annually, accounting for 7.69% of the total water consumption in 2023. This initiative aims to conserve water resources.

Waste Management

To ensure sustainable resource use and proper waste disposal, EIKEI Group has established internal waste management regulations based on the ISO14001 environmental management system. Waste management is divided into three main aspects: resource recycling, incineration (energy recovery), and proper waste disposal. EIKEI Group waste management complies with the "Waste Disposal Act" to fulfill the responsibility of proper waste disposal. Additionally, the Taiwan branch plans to switch to more environmentally friendly printing paper starting in 2024; the Thailand subsidiary also plans to use recycled pulp for packaging materials starting in 2024.

Waste Disposal Process

EIKEI Group ensures that all waste generated from operational activities within the plant is managed according to internal waste management regulations and legal requirements. Waste produced in the plant is categorized, collected, and stored based on waste type and compatibility. Through irregular inspections of the plant's waste storage areas and vendor removal operations, we ensure that waste disposal complies with regulations, preventing environmental pollution and safety hazards.

EIKEI Group does not have its own factory, so the main waste consists of general business waste and a small amount of inventory. General business waste includes paper, kitchen waste, and other general garbage generated from operations, which is assisted by building property management for removal. Internally, the company periodically promotes waste classification, reduction, and the implementation of electronic processes to reduce paper waste.

In the Thailand and Shenzhen offices, small warehouses are set up to assist customers in managing inventory. Occasionally, a small amount of inventory is scrapped due to NG (No Good) or testing factors. When scrapped, the inventory is classified as hazardous business waste. The company conducts one to two scrapping operations annually in conjunction with inventory checks and hires qualified recyclers for removal.